The New Paradigm for Drones Enters Production in a Print Farm

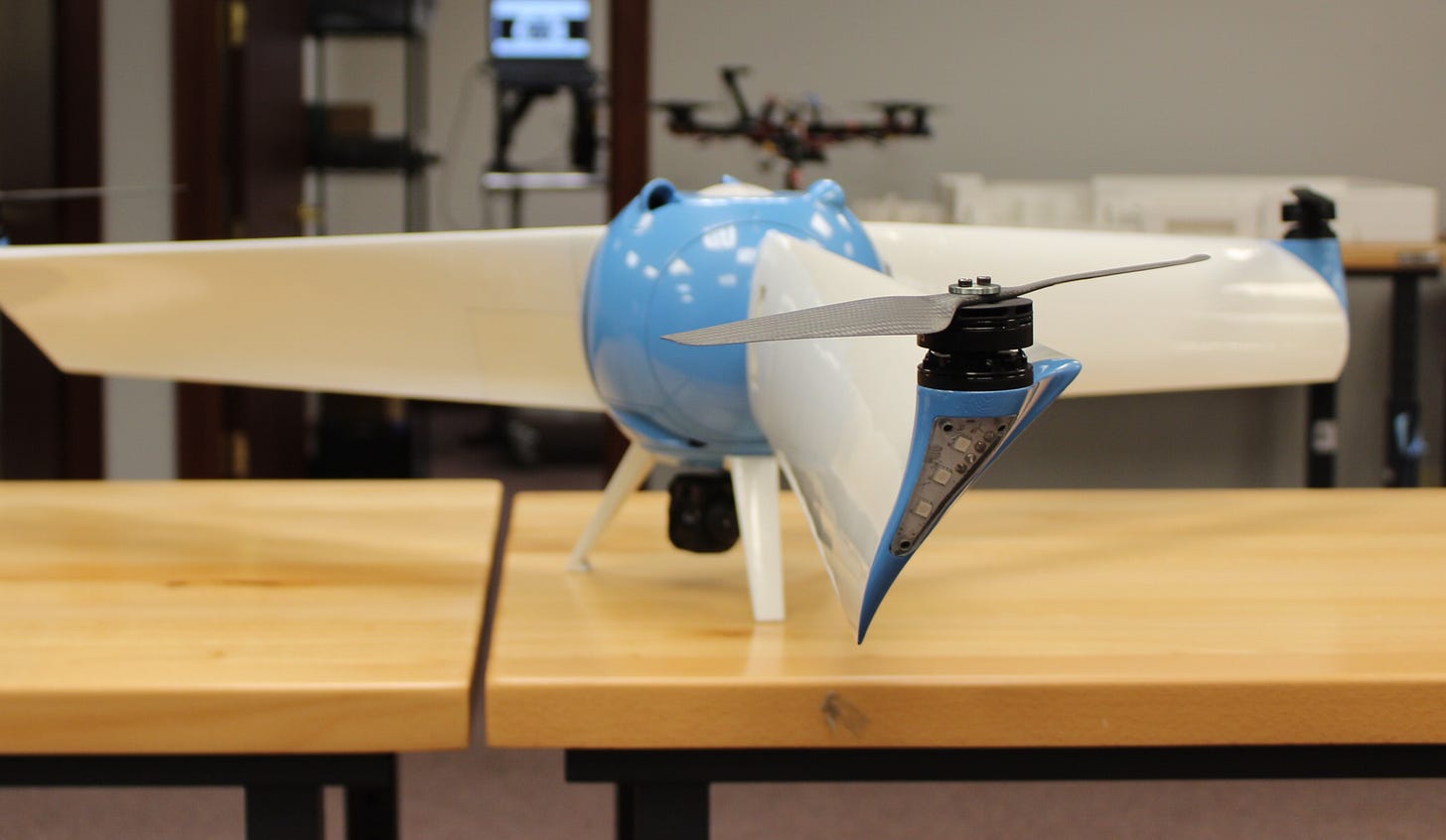

Angel Aerial Systems pioneers low-cost, long-endurance drone flight through its “windmill” design. Manufacturing is vertically integrated, and scalable in small dollar amounts at a time.

Welcome to the Zelinski Report. I’m glad you’re here. I am Peter Zelinski, a writer and journalist reporting on manufacturing technology, the beat I have covered for over 25 years.

This newsletter will be equal parts reporting and commentary. My aim is to explore how manufacturing is changing, how the technology of manufacturing is changing, how these changes interconnect and affect our world, and what each development might offer or mean for those who are building businesses or careers connected to manufacturing’s success.

If you have subscribed, thank you. If you have not yet subscribed, please consider doing so. I will post when I post—subscribing ensures you won’t miss it when I share something new.

Here now is the Zelinski Report’s first post, about a technology startup advancing two interrelated ideas: a new concept for long-endurance drones and an unusual plan for how to produce them.

Angel Aerial Systems is reimagining the way drones fly.

The challenge with drones, notably the quadcopter design that is common among drones today, is flight time. How can the drone be reconceived to extend its flight endurance without increasing cost? Can this be done by increasing battery size? Answer: No, not by enlarging the battery….

But instead by transforming the entire drone body into the propeller that keeps it aloft.

Angel CEO and co-founder Will Hasting (left in the photo above) is working to develop this design, leading the team now bringing this concept to market. The quadcopter and drone concepts like it, he says, “are based on conventional airframe designs conceived in the twentieth century.” That is, during the time of manned flight. The expectation of a pilot or passenger still haunts design assumptions, without this unnecessary consideration being seen. Take away this consideration, fully accept unmanned flight, and, he says, “It reopens the design space. The time is ripe to imagine what the drone airframe looks like for the twenty-first century.”

And the company realizing this idea is doing so using a production system that is almost entirely vertically integrated, while also imposing little in terms of footprint or capital cost.

A row of desktop 3D printers produces all the drone structural components, along with the shell for the controller.

So while this startup is rethinking how long a lightweight aircraft can remain in the air, it is also reevaluating how far low-cost equipment can go to support the company’s production.

Anything Can Be a Weapon—What Else Can You Do?

Hasting, a Navy veteran and engineer who in previous roles has worked in both aerospace and additive manufacturing, was inspired to launch this startup by the war in Ukraine. He says he was moved by the suffering of this war and wanted to be of help. At the same time, he learned of a Defense Advanced Research Projects Agency (DARPA) request for low-cost, long-endurance, loitering drones for Navy and Marine missions.

Hasting pursued but never won the project award. And during the pursuit, he elicited feedback from a mentor. University of Cincinnati aerospace engineering professor Kelly Cohen offered the perspective that changed his direction.

“Dr. Cohen said, ‘You can make a weapon out of anything,’” Hasting recalls. “He challenged whether we could ‘do something good in the world’ instead.”

Another use for long-endurance hovering drones presented itself. Hasting learned of a police search in Indiana for an elderly man lost in the woods, a search that was confounded by limited drone battery life and the resulting inability to fully cover the search area, even with three quadcopter drones in the air.

Angel redirected its efforts toward local-community first responders: police, rescue, firefighters. This is the market—safety and protection—that the company is now manufacturing long-endurance drones to serve.

On Standard Drones, Too Much Mass Is Non-Performing

The Angel drone design, named the Trio, is a departure from the quadcopter design. On the quadcopter, four propellers carry a roughly square-shaped drone into the air.

The Trio is shaped like a Y, with three propellers, one at the end of each arm. The propellers provide for the initial takeoff and vertical ascent.

Then, the drone enters “windmill mode.” The propeller arms all pivot, driving the drone to rotate, and each arm of the Y serves as an airfoil as the entire drone spins to move through the air. Play the video to see this:

On a quadcopter, much of the drone mass is non-performing, carried by the propellers. During the Angel drone’s windmill mode, as the drone spins, nearly the entire airframe is employed to generate lift.

The difference translates to a dramatic difference in flying time. Compared to the quadcopter drone model most widely used by first responders, Angel’s Trio can remain in the air 3 to 6 times as long before recharging.

The spinning drone can still carry a payload. This is attached via a turret at the center that is counter-rotated via a fourth internal motor. The turret is spun in a contrary direction that perfectly offsets the windmill. Thus, a mounted camera remains fixed and stationary while the drone hovers for hours in windmill mode above whatever scene the camera is watching.

How AI, AM and Amazon Transform Possibilities for Technology Startups

This new method of making a drone fly was developed and brought to market within a window of about two years. Hasting describes why engineering entrepreneurs now live in a new world of accelerated possibility. At the major aerospace company for which he worked until 2019, the challenges of a large organization might have extended a project of this ambition to over a decade or more, he says, and even the nimbler metal AM company for which he worked until 2022 would likely have had difficulty iterating at Angel’s speed.

He credits three advances for the development speed now possible, at least one of which is unsung. They are: artificial intelligence, 3D printing, and overnight shipping sources following the example of Amazon Prime.

What all these resources have in common is the way they collapse delays that would otherwise halt progress.

“AI is helping us diagnose and overcome engineering problems much faster than traditional analysis methods,” he says. Generative AI can point to answers that would otherwise require effort and delay to search and synthesize. Meanwhile, “3D printing and the new sophisticated filaments available for it let us speed through 30 design options in a couple weeks.” And specialized hardware that previously would have imposed a long shipping wait is now frequently available overnight, sometimes through Amazon, or often through industrial providers operating at the same speed.

The rapid access to needed hardware is the unsung enabler, just as valuable as AI and additive manufacturing. Angel’s vertical integration extends to producing its own electronics in-house, including developing circuit boards that conform to geometric spaces in the drone. Overnight delivery of electronics parts supports the speed of this development.

All these resources in combination—AI plus AM plus Amazon-like delivery—have proven to be combustion for accelerating Angel’s innovation.

If You Engineer Cost into a System, It Is Hard to Get It Out

The drone components largely must be 3D printed, not injection molded, because large hollow spaces for weight savings create geometries that require 3D printing to produce.

In the meantime, 3D printing creates opportunities for assembly consolidation. The Angel drone body as it currently exists consists of 12 major components, all 3D printed. Assembling a drone is a straightforward task easily performed by the company’s one 3D printer technician as the machines are printing.

Materials are ASA and nylon. The Prusa HT90 machines Angel uses feature heated chambers, though the company is operating them at their temperature limits to work with the material as productively as it can with the needed part-to-part repeatability.

These are, to an extent, high-end consumer or engineering 3D printers. An industrial-production polymer AM system could possibly print each part faster—though Hasting is not sure of this. He notes the longest Prusa print cycle for one of the drone components is 2 days, a cycle time not set by the printer itself. “For our carbon-fiber-filled materials, the filament limits the speed. So you’re speed-limited regardless of the printer, unless you use multiple extruders,” he says.

Meanwhile, each of these 3D printers costs about $10,000. The opportunity Hasting sees in this is that, for the price of an industrial polymer AM system, he says, the company could add somewhere in the range of 10 to 40 more of these machines. Hasting therefore wants to design the drone and engineer its components to accept the constraints of the Prusa machines and continue to rely on a printer like this for production.

He says, “Once you design cost into a product, it’s hard to get it out.”

His expectation is that Angel will scale up drone production through the addition of perhaps dozens more desktop 3D printers.

In the follow-up to this article, I plan to consider that choice. I will be posting a video filmed at Angel Aerial Systems that analyzes the print farm as a means of production, considering cost, labor and scaling among other factors. To make sure you are alerted when that video appears, be sure to subscribe:

Photography: Audrey Zelinski