The Case for Patient-Matched Implants Made Possible via AM

Orthopedic implants do not fit the model of one size fits all, and arguably not even the model of many sizes fit all.

How valuable are non-standard medical devices when it comes to the needs of our individually unique human bodies?

Orthopedic implants are typically made to standard sizes because established production methods demand scaling and standardization. In most production methods, changing a design detail of the part imposes a cost for the tooling or setup change needed.

Additive manufacturing (AM) transcends this limitation because there is no cost for design change from one part to the next. In this digital production method, a batch of parts in which every one is different can be made (at least as far as the additive process goes) as efficiently as a batch in which every part is alike.

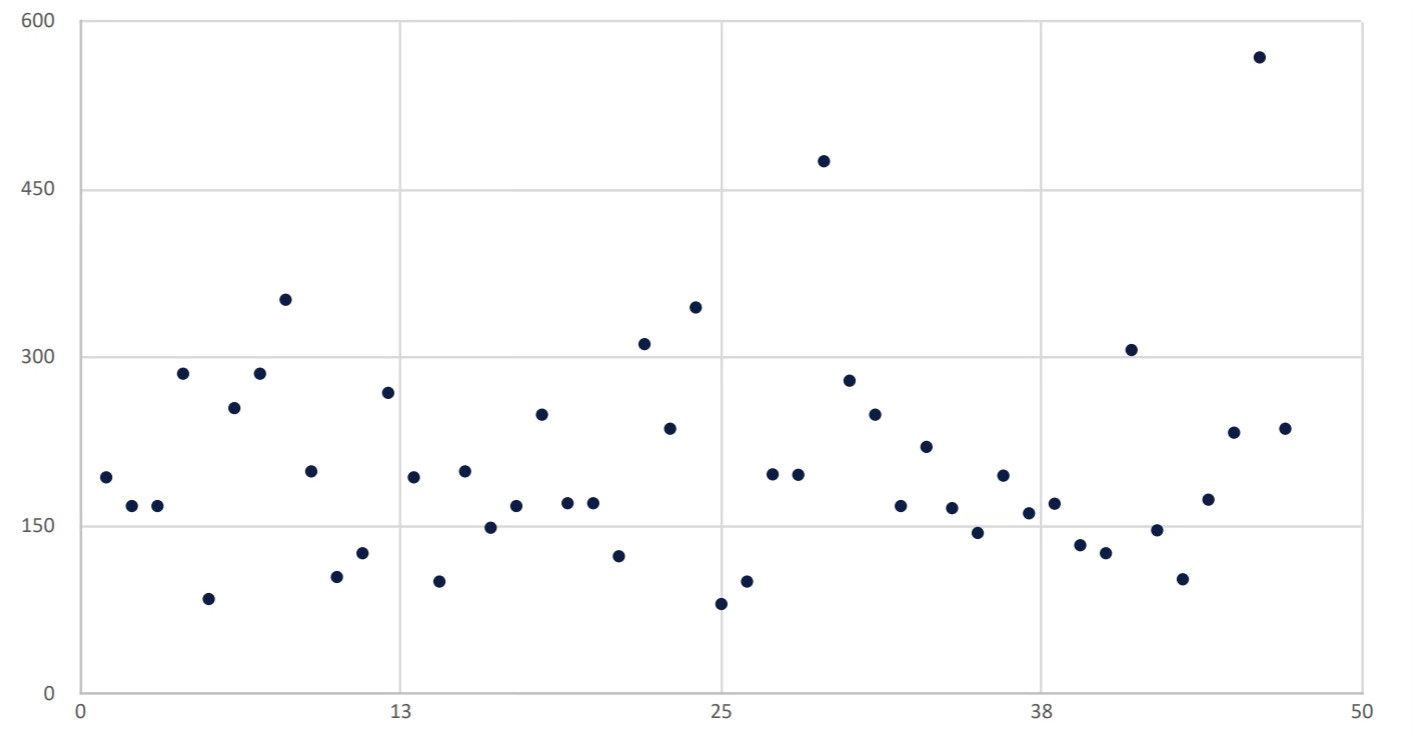

The scatter chart below suggests how valuable this freedom will ultimately prove to be for orthopedic manufacturing. This chart comes from ALM Ortho, a Maine-based company specializing in patient-matched implants designed from patient data and made through additive manufacturing (electron beam melting) according to the instructions of surgeons.

The chart shows the cross-sectional areas for 47 patient-matched implants. The implants are all of the same type: bone-anchored osseointegrated implants for limb-loss sufferers, allowing for a secure connection to the prosthetic limb. (See an example in this article.) Yet as these data show, there is no sameness to be found in the distribution of the needs of these individual patients.

Orthopedic implants obviously are not “one size fits all.” However, even the model of “many sizes fit all” does not conform to this data set. If “many sizes fit all” could serve this patient set well, then we would see clustering around certain sizes. The scatter is more diffuse than this, revealing how varied human bodies are—or how valuable additive manufacturing will prove to be in making medical devices that serve individual patients better than has even been economically feasible before.