Rather Than Process Perfection, Optimize for Material Forgiveness

Phaseshift sees the path for scaling AM and distributed manufacturing in materials engineering using AI.

My early belief about the power of AI for additive manufacturing saw AI’s value in fine-tuning parameters. That is, using AI to map all the interactions between input and output for an AM process, allowing AI to be the master tuner, optimizing process input variables to obtain the precisely desired outputs in terms of the fidelity of the complex 3D printed geometry and the material properties required.

However, a recent conversation with Fazal Mahmood, CEO and cofounder of Phaseshift, opened my eyes to a different and perhaps more resilient optimization path for AI and its use for AM.

Rather than tuning the process, why not use AI to tune the composition of the material? With AI optimizing material composition for desired properties, printability can be one of the properties optimized for. A suboptimized hard material might need just the right build design and parameter set during printing, or else it will crack. But a material optimized for both hardness and printability is more forgiving of variations in parameter or process choices.

AI Balances Multiple Goals

Based in Toronto, Phaseshift is a materials engineering startup focused on this work: using simulation plus AI to design new materials matching user-defined needs. That includes tailoring the material for success in its intended production method, which for most of the company’s work is AM, specifically laser powder bed fusion. Rather than discovering just the right combination of laser power, scan speed, hatch spacing, layer thickness and orientation choices for a given material, and fighting these parameters to make the material behave, the company can engineer materials for compliance within a generous working range.

Process optimization is therefore NBD.

Getting to this goal is the chief use of AI. Simulation, guided by the human expertise of Phaseshift’s team, establishes the physics landscape governing the new material.

Mahmood says, “AI doesn’t do simulation. AI is more like: How can I balance all the different aims together? The main thing we use AI for is optimizing chemistry for multiple objectives.”

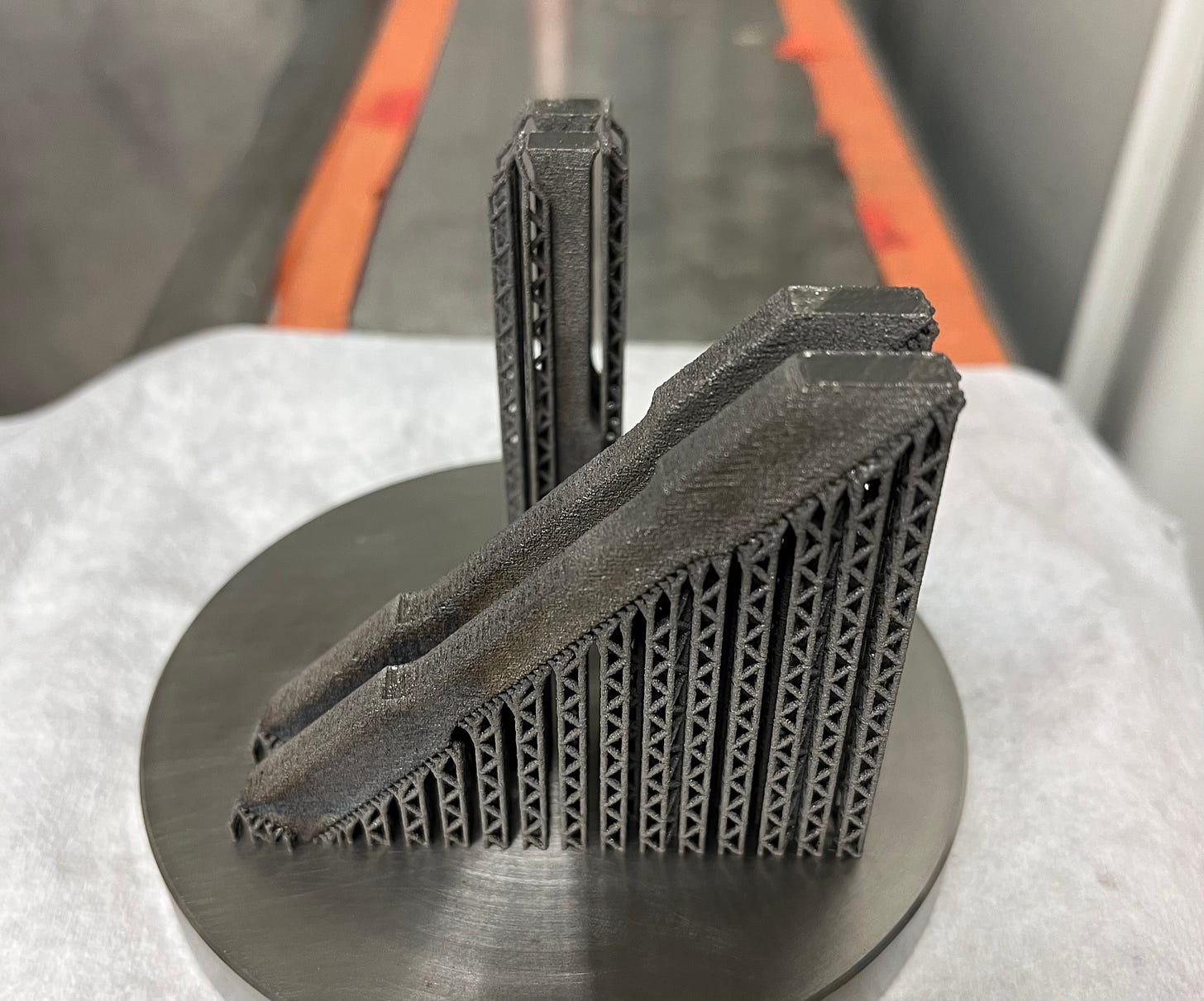

The photo shows an example. The parts are made of a cermet—ceramic-metal composite—engineered with printability as one of the objectives. The parts were 3D printed successfully (no defects or cracking) via laser powder bed fusion without special process considerations, and without even follow-up operations.

“We reached 97 to 99 percent density with a simple 250-watt laser printer, with no base plate heating and no post processing,” Mahmood says.

This is a notable success for cermet even apart from additive. The conventional method of manufacturing with cermet generally involves powder metallurgy followed by sintering.

With additive, he says, “One of the biggest issues right now is that most materials are incredibly picky. If the printer settings are off by even a tiny bit, the part cracks or fails.”

That is where AI comes in. “AI scans through a combinatorially explosive space, a puzzle too big for human intuition, to find the rare recipes that are stable across a broader range of processing parameters.” That stability is what is meant by “forgiving.”

“The success we have had with cermets is a great example of this,” he says.

Simplicity Scales

Mahmood believes the real value of this printability optimization, and the simplicity it brings, may be in distributed manufacturing. That is, the promise of being able to quickly manufacture a part close to its point of use by sending the file to an AM machine in that location. Optimized processes do not help with distributed manufacturing, because the process then has to be perfect in every location.

“If you need a perfect, lab-controlled environment to print a part, you can’t use 3D printing in the real world, like at a remote mine or a military base,” he says. But materials optimization can deliver parts forgiving enough to be printed anywhere.

“You don’t want a solution that works in a very tightly controlled set of parameters,” Mahmood says. “You want something that a broad range of suppliers can print and supply. That’s what will really help us scale.”