Osseointegration and Additive Manufacturing

How manufacturing technology is advancing options for surgeons.

One of the challenges inherent to realizing additive manufacturing’s promise is the need to go beyond manufacturers.

The case has to be made to non-manufacturers as well, the ones who benefit from the new products and new functionality that a new method of manufacturing makes possible. Indeed, this is the more important group to reach!

I co-wrote an article with Brian McLaughlin, co-founder of medical device manufacturer ALM Ortho, with this aim in mind. The piece aims to reach orthopedic surgeons and the stakeholders near them to explain what today’s manufacturing technology is doing for osseointegration—or the capacity for the natural in-growth of bone to provide secure fixation of orthopedic implants.

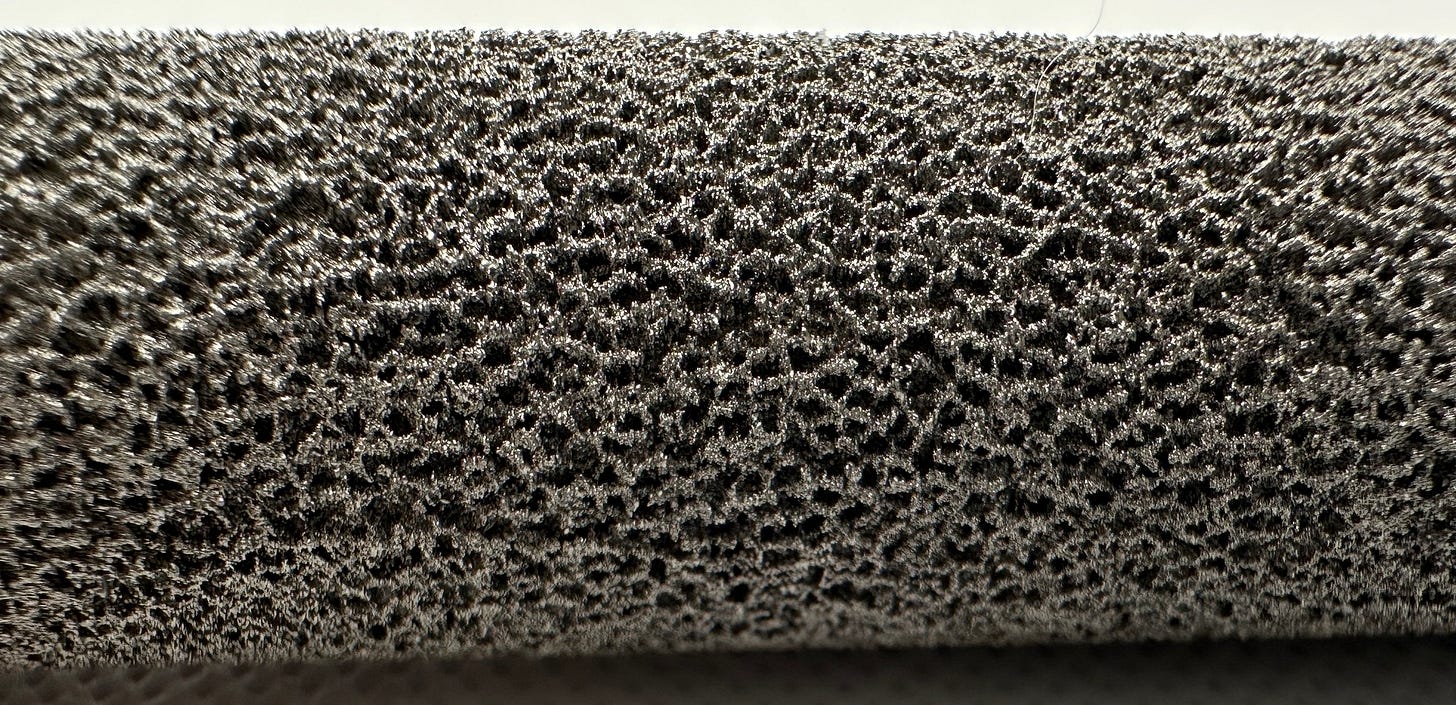

ALM Ortho is an osseointegration specialist. The company works with surgeons to create patient-matched implants leveraging the trabecular lattice surface geometries encouraging osseointegration that the company can achieve through additive manufacturing—specifically through electron beam melting on machines from Colibrium Additive.

But a major obstacle is perception-related. Just how good additive manufacturing is for osseointegration is hard to appreciate from a perspective removed from the design and production of the part. Just how far additive has advanced osseointegration in recent times is hard to see. Indeed, many in the medical field do not recognize that osseointegration is a frontier. They see it as an attribute instead, something the implant either has or doesn’t have. In fact, osseointegration is a technology that has advanced considerably now that we have digital methods to produce precisely the intricate surface geometry that can encourage bone to grow around and through it.

One recent result is varieties of implants that could not work as effectively as they do without the advances osseointegration has made. An example is patient-matched bone-anchored implants that have brought new possibilities for secure prosthetic limb attachment for some limb-loss patients. The article describes additive manufacturing’s role for these implants in this way:

Additive manufacturing allows for complex geometry not only in the sense of the intricate lattice forms encouraging osseointegration, but in another sense as well. Additive manufacturing also enables the complexity of manufacturing implants that are different from one patient to the next.

Example: A bone-anchor implant manufactured to suit a particular limb-loss patient identified by a surgeon will perfectly fit that patient, following the length and curvature of that patient’s (remaining) bone. The implant is unique to the patient and fits that patient alone.

These two uses of additive manufacturing go together. Patient-matched design enables a fit that serves osseointegration, because the tailor-made form of the device helps maximize contact between bone surface and implant surface. Meanwhile, the patient-specific device generally needs osseointegration, relying on this for fixation. The departure from a standard design means departing from established connection points for standard fasteners such as screws through a titanium rod. For the orthopedic implant that has been suited to the patient’s bone, the patient’s bone itself is the best and potentially essential means of affixing the device.

The full article is worth a read even if you are not in the medical field. Additive is realizing major new possibilities in different ways in various specialized fields. As with the outreach to medical professionals here, we need to go into each of these specialized fields to explain what options the changes in manufacturing are now making possible.